Top 3D Printing Solutions By By3Design

With the fast changes happening in technology, 3D printing is changing how products are made. By3Design is leading the way in this modern technology, giving businesses in Phoenix an advantage. Through our advanced printing technology, we can create detailed designs with great accuracy. This helps to speed up your product development and make your ideas come alive.

Understanding 3D Printing Technology

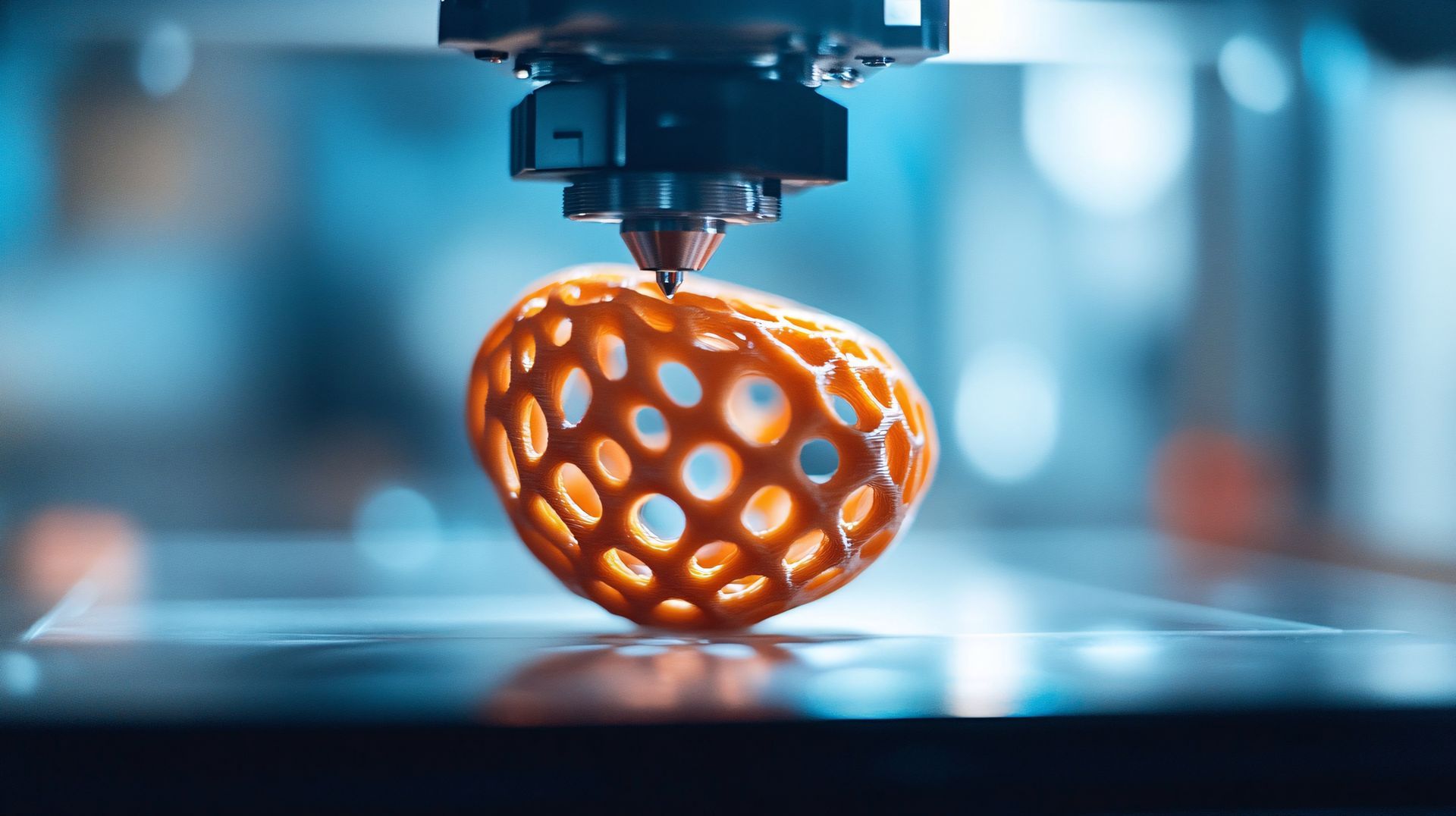

3D printing, which some call additive manufacturing, has changed from something that seemed like science fiction to a crucial tool used in many fields. So, what makes this printing process so special? With 3D printing, objects are built layer by layer from a digital design, unlike traditional methods that take away material. This method offers amazing design freedom, allowing the creation of complex geometries that can't easily be made with normal techniques.

Among the biggest benefits of 3D printing is its ability for rapid prototyping. Designers and engineers can turn their ideas into real models in a short time, leading to quick changes and improvements. Besides that, this technology supports various material types, each having special properties for different uses. From sturdy Nylon and ABS plastics to high-quality resins, 3D printing gives the flexibility necessary for ongoing innovation in different industries.

The Evolution Of 3D Printing

3D printing, which started as a small tech used only in research labs, has changed a lot and now plays a vital role in modern technology and industrial applications. The process began with simple systems mainly for basic prototyping. Through ongoing improvements, advanced techniques have appeared, like powder bed fusion, stereolithography (SLA), and fused deposition modeling (FDM), each with their own special features.

With powder bed fusion methods such as selective laser sintering (SLS), a new age of precision manufacturing has begun. By effectively fusing layers of powdered materials with a laser, SLS allows the creation of strong and detailed parts with great accuracy. This innovation has led to opportunities for manufacturers in many fields like aerospace, automotive, and medical, allowing them to create end-use components that have complex geometries and outstanding material qualities.

While 3D printing technology grows, its affordability and accessibility have improved a lot, making it an option for various businesses. From small startups to large corporations, companies are using this game-changing technology to enhance their manufacturing processes, shorten lead times, and explore new design possibilities in a broad range of industrial applications.

How 3D Printing Works: The Basics

At its heart, the magic of 3D printing in Phoenix comes from creating three-dimensional objects slowly, using layers built from a digital design. Various technologies like FDM, SLA, and sintering are involved in this. With the creation of a 3D model, Computer-Aided Design (CAD) software is used. This digital plan acts like an instruction manual for the 3D printer, helping it step by step to bring the design to life.

With FDM, one of the most common techniques in 3D printing, the process runs on a simple idea. A thermoplastic filament gets heated until it melts and is then pushed out through a nozzle onto a build platform. The nozzle moves along the X, Y, and Z directions, adding layers of material one at a time. This continues until the material hardens to create the shape we want.

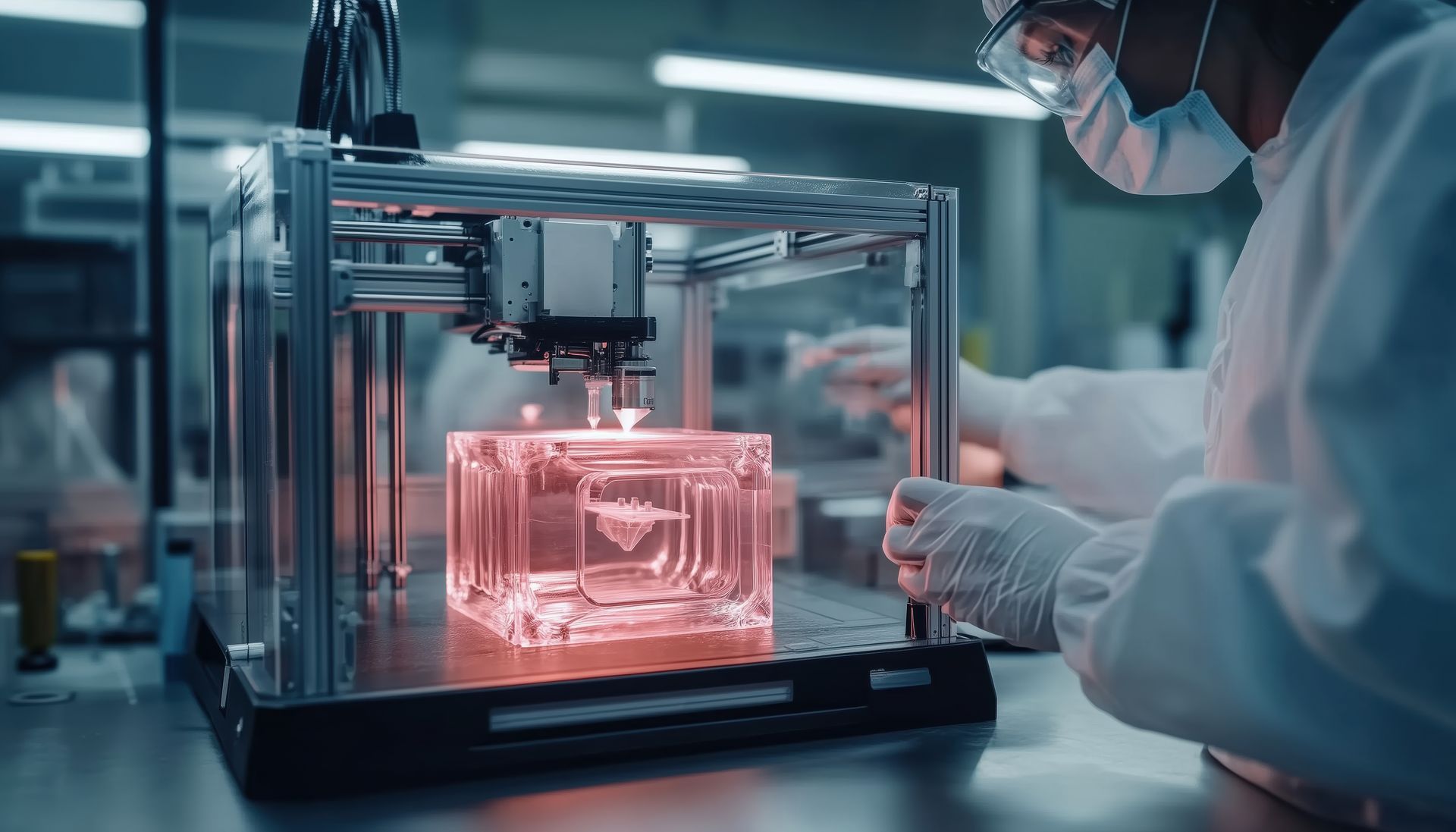

SLA, in contrast, uses ultraviolet (UV) light to harden liquid resin. A UV laser carefully draws the shape's cross-sections in a tank of photosensitive resin, solidifying only certain areas. As the build platform sinks lower, the printed item comes out of the resin bath, layer by layer. This happens with great accuracy, leaving a smooth surface in the end.

By3Design's Unique Approach To 3D Printing

By3Design stands out in the Phoenix, AZ, area because we provide more than just a service; instead, we create tailored solutions. By understanding that every project has its own unique needs, our team collaborates closely with you. Whether you need prototyping, on-demand manufacturing, or low-volume production runs, we are here to help.

With a focus on quick turnaround times, we are proud to deliver quality without cutting corners. In Phoenix, AZ, our efficient process boosts production and delivery, ensuring your products reach the market sooner. Thanks to our dedication to precision, quality, and quick turnaround times, we have become the preferred 3D printing partner for businesses in many different industries.

Tailored Solutions For Phoenix's Climate Challenges

The climate in Phoenix, with its extreme heat and dryness, brings special challenges for materials. Because of this, By3Design chooses strong materials like PETG and ABS to make sure your products can handle the tough conditions in the area. These materials offer high strength, keep their shape, and resist UV damage, which makes them perfect for outdoor uses.

In addition to picking the right materials, our team works on the 3D printing process. They adjust settings like layer height, infill density, and printing temperature to get the right strength and durability needed for the environment in Phoenix. By changing these settings carefully, we improve the printed parts' properties, so they avoid issues like warping, cracking, or getting weak in the blazing desert sun.

Whether you need a prototype for an outdoor sensor network, special tools for car manufacturing, or models for architectural displays under the Arizona sun, By3Design's knowledge in material choice and printing process adjustments guarantees your 3D printed products will be made to last.

Emphasizing Durability And Efficiency

At By3Design, we really care about using the best manufacturing technologies, like Selective Laser Sintering (SLS) and Multi Jet Fusion (MJF). With these technologies, we can create high-quality, intricate designs that have great strength and durability. In our work, we focus on speed and precision, so your project will not just meet but go beyond what you expect.

About our commitment to efficiency, it goes further than just how we make things. We make our workflow smoother at every step, starting from design consultation through to delivering the final product. This means:

- Faster turnaround times: We know how important it is to get your products out quickly.

- Competitive pricing: Because of our efficient manufacturing process, we can provide competitive prices without losing quality.

- Reduced waste: Additive manufacturing produces less waste than traditional methods.

By always improving our skills and keeping up with new advancements, we make sure your projects get the benefits of the best 3D printing solutions.

The Industries We Serve

By3Design serves many different industries, using our knowledge to provide tailored solutions. With our skills in rapid prototyping and our dedication to accuracy and quality, we are a great partner for businesses in the automotive, aerospace, and robotics fields, along with others.

For a unique prototype or a small production order, we have the know-how and technology to turn your ideas into reality. With a focus on staying updated with the latest trends and developments in the industry, our team makes sure to meet the changing needs of various sectors.

Automotive: Driving Innovation With 3D Printing

The automotive industry thrives on innovation, and 3D printing has become an indispensable tool within this sector. By3Design recognizes the need for speed and agility in automotive product development. Our rapid prototyping services enable manufacturers to move quickly from concept to physical model, accelerating design cycles and reducing time to market.

Beyond prototyping, By3Design's 3D printing phoenix solutions extend to manufacturing essential tooling and fixtures. We produce custom jigs, fixtures, and assembly aids tailored to the specific needs of automotive production lines. These precisely engineered tools enhance assembly processes, improve ergonomic efficiency, and ensure consistent quality in vehicle manufacturing.

| Application | Benefit |

|---|---|

| Rapid Prototyping | Accelerate the design and development of new components, from intricate engine parts to ergonomic interior elements. |

| Custom Tooling & Fixtures | Create tailored jigs and fixtures that enhance assembly accuracy and efficiency on the production line. |

| On-Demand Manufacturing | Produce low-volume or customized parts on demand, reducing the need for large inventories. |

Aerospace: Soaring High With Advanced Manufacturing

The aerospace industry needs exact precision, light materials that are also strong, and the ability to make complex shapes. With By3Design's advanced 3D printing capabilities, we aim to meet these tough standards. Our team works with high-quality materials like Nylon and ULTEM™ 9085 resin, which are both recognized for their great strength-to-weight ratios and resistance to heat and chemicals.

Through lightweighting aircraft parts and creating detailed components for drones and satellites, 3D printing helps aerospace engineers explore new design possibilities. We work closely with clients, using CAD models to ensure accuracy and quality throughout the manufacturing process.

At By3Design, we feel proud to support the future of the aerospace industry by providing creative manufacturing solutions. These solutions help create lighter and more efficient aircraft and space exploration vehicles.

Conclusion

By3Design provides modern 3D printing solutions that fit the specific needs of Phoenix. With an emphasis on being durable and efficient, By3Design transforms industries such as automotive and aerospace. Through their creative methods, they demonstrate how advanced manufacturing can spark new ideas. For customized 3D printing solutions that perform well in Phoenix's environment, reach out to By3Design today.

Navigation Links:

Contact Us:

Powered by Rae of Light SEO