The Impact of 3D Printing on Traditional Manufacturing

3D printing has revolutionized traditional manufacturing, allowing businesses to innovate and streamline production processes. With Phoenix 3D printing advancements, manufacturers can reduce costs, improve product quality, and shorten timelines. This technology is reshaping industries by enabling faster prototyping, customization, and even small-batch production. In this post, we will explore how 3D printing impacts traditional manufacturing and the broader implications for the industry.

Prototyping and Product Testing Without the Need for Molds

1. Faster Prototyping

3D printing eliminates the need for molds, making prototyping faster and more affordable. Traditional methods require the creation of molds, which can be expensive and time-consuming, especially for complex designs. With 3D printing, manufacturers can produce prototypes quickly, enabling them to test and modify designs without the delay and cost of mold production.

2. Design Iterations

With 3D printing, manufacturers can easily iterate on designs. Instead of waiting weeks or months for new molds, they can make changes and reprint a prototype within hours. This rapid iteration process helps reduce product development times, allowing companies to refine their designs much more efficiently.

3. Risk Reduction

By using 3D printing for prototyping, manufacturers can test the functionality of their products before committing to expensive mass production. This helps identify design flaws early in the process, reducing the risk of costly mistakes when scaling up production.

4. Cost Efficiency

Traditional mold-making processes can be prohibitively expensive, especially for low-volume production or prototype testing. 3D printing allows companies to save on mold costs by directly printing prototypes, reducing upfront investments. This makes product development more accessible for smaller businesses and startups, encouraging innovation without the heavy financial burden of mold production.

Reducing the Reliance on Mass Production and Long Supply Chains

1. On-Demand Production

3D printing enables businesses to produce items on demand rather than relying on traditional mass production methods. Instead of creating large inventories, businesses can print products only when needed, minimizing waste and reducing storage costs. This on-demand production model is especially valuable for industries where demand is unpredictable or fluctuates frequently.

2. Localized Manufacturing

Traditional manufacturing relies heavily on global supply chains, which can be disrupted by factors like shipping delays or political instability. With 3D printing, manufacturers can produce goods locally, reducing dependence on far-flung suppliers and improving supply chain resilience.

3. Environmental Impact

3D printing is more sustainable than traditional manufacturing methods because it uses only the material needed for each part. This helps reduce waste and lowers the carbon footprint associated with mass production and long-distance shipping.

4. Improved Lead Times

3D printing reduces lead times significantly compared to traditional manufacturing processes. With the ability to produce products quickly and locally, businesses can meet customer demands faster. This also means quicker responses to market trends or disruptions in demand, enhancing overall supply chain agility and reducing downtime between production runs.

How 3D Printing Allows for Small-Batch and On-Demand Production

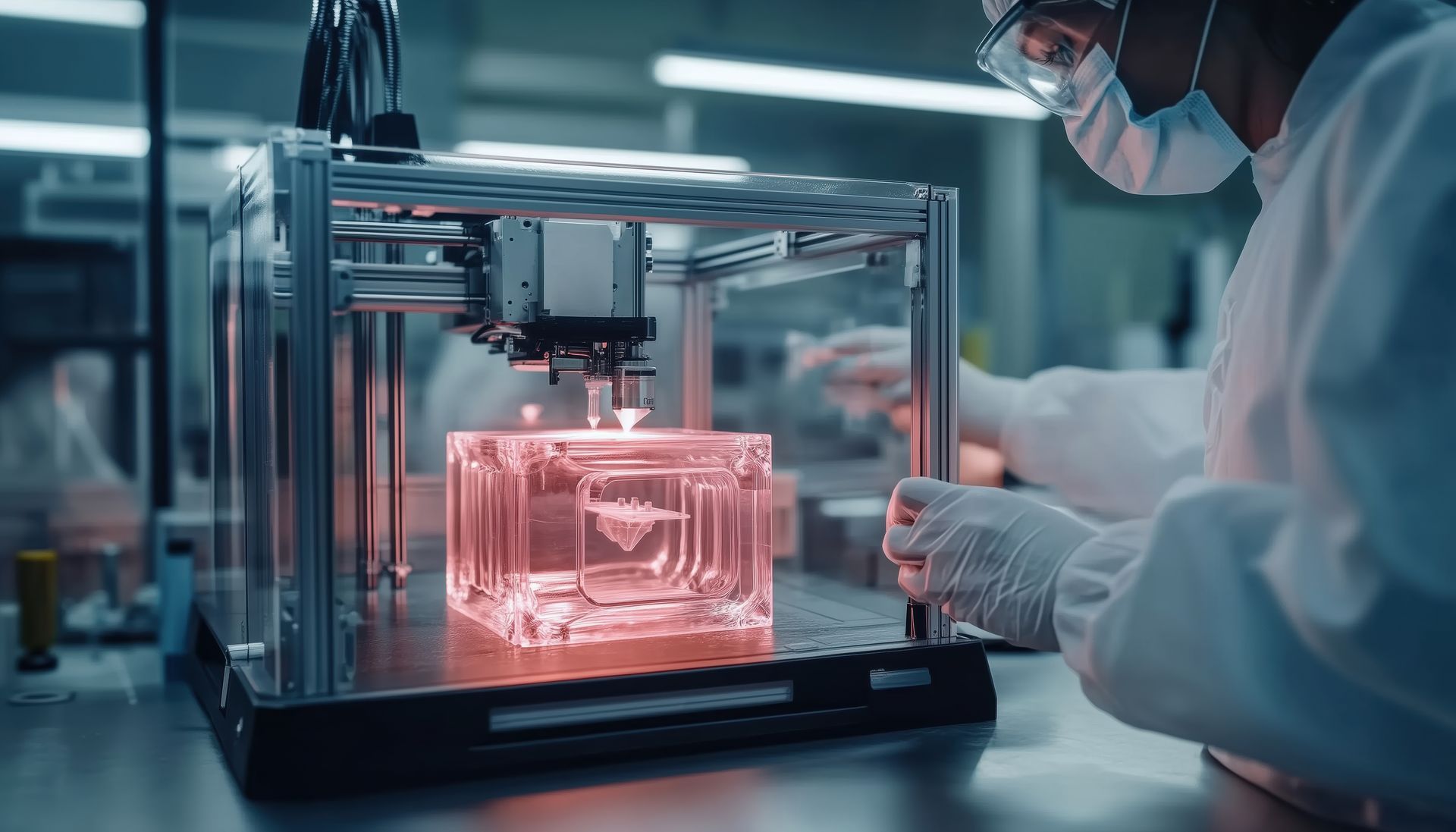

1. Customization

The capacity to create unique items is a big plus of 3D printing. Unlike traditional manufacturing, which often requires large batches to justify setup costs, 3D printing allows manufacturers to create one-of-a-kind products without additional expense. This makes it ideal for industries where customization is a key selling point, such as fashion or healthcare.

2. Cost-Effective for Low Volume

For small businesses or startups, mass production methods can be financially prohibitive due to high upfront costs. 3D printing allows businesses to create small batches or even individual units without the heavy costs associated with traditional production. This reduces financial risk and makes small-batch production more accessible.

3. Agile Manufacturing

3D printing enables manufacturers to respond quickly to changes in consumer demand. Because production setups are faster and cheaper than traditional manufacturing processes, companies can easily adjust their production runs based on market needs, allowing for greater agility and responsiveness.

4. Rapid Prototyping for Custom Orders

With 3D printing, businesses can quickly create prototypes of customized products, ensuring a faster turnaround for customer orders. Whether it’s personalized jewelry, custom packaging, or tailored medical devices, 3D printing allows for quick adjustments to design specifications, reducing the wait time for customers and speeding up the order fulfillment process.

The Future of Manufacturing: Blending Traditional and Additive Methods

1. Hybrid Manufacturing Models

Rather than replacing traditional methods, 3D printing is increasingly being integrated into existing production processes. For example, 3D printing can be used to create highly specialized parts, which are then integrated into products manufactured through conventional means. This hybrid approach combines the strengths of both methods, improving efficiency and flexibility.

2. Cost Efficiency in High-Volume Production

While 3D printing is ideal for prototyping and small-batch production, it’s also increasingly being used for high-volume production. As 3D printing technology advances, it’s becoming more cost-effective for larger runs. In the future, we may see industries using 3D printing for everything from low-cost custom parts to mass-produced products.

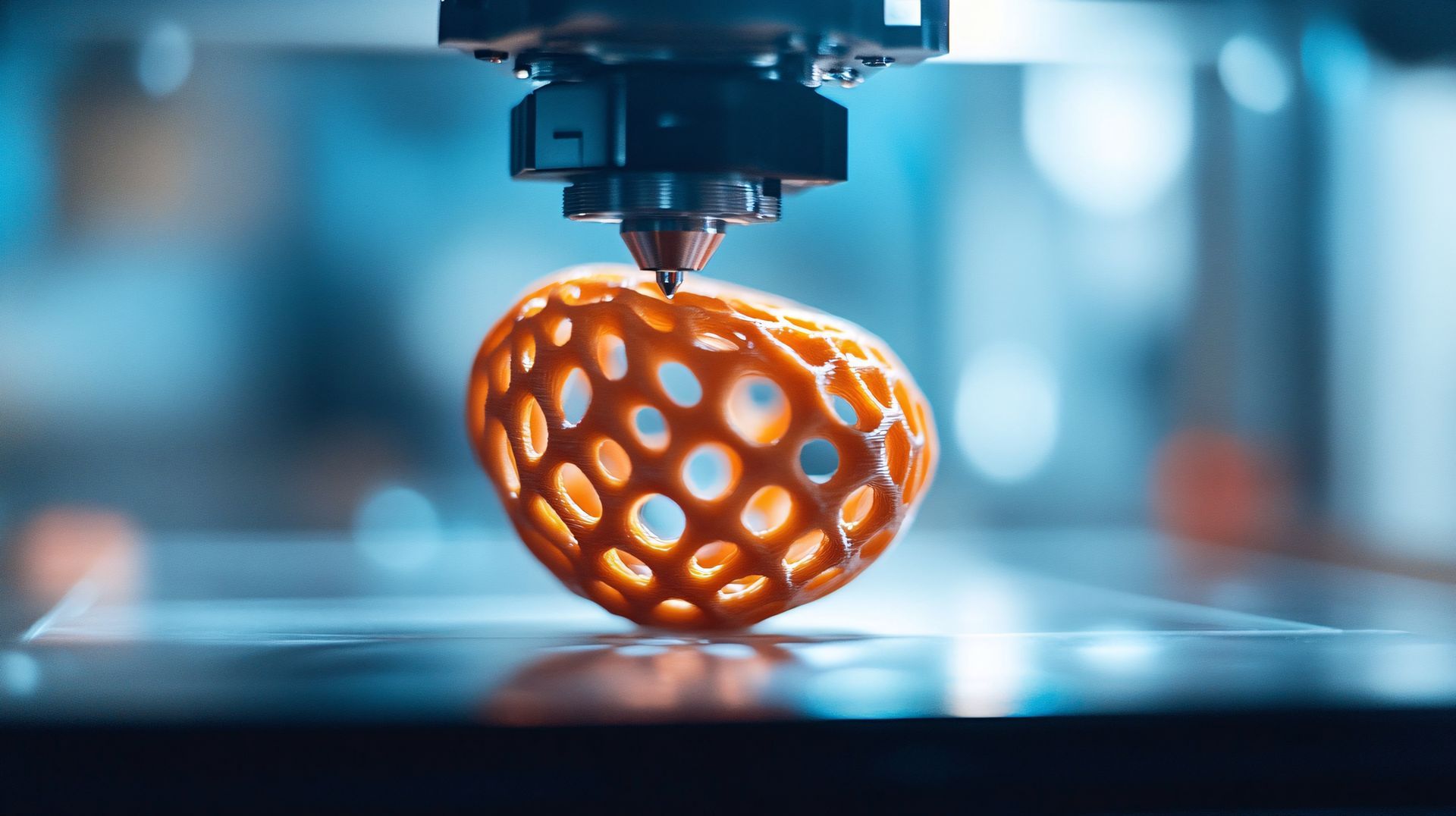

3. Complex Designs Made Simple

3D printing allows manufacturers to produce complex designs that would be difficult or impossible to make using traditional methods. For example, components with intricate geometries or internal features can be easily produced with 3D printing, adding value and reducing production time. This capability will play an important role in the future of product design and manufacturing. Learn more about how professionals handle your 3D printing project when you read “Cutting-Edge 3D Printing Solutions By By3Design.”

4. Sustainability through Reduced Waste

3D printing offers a more sustainable approach to manufacturing by minimizing material waste. Unlike traditional methods, where excess material is cut away or discarded, 3D printing builds up products layer by layer, using only the exact amount of material required. This contributes to a more sustainable manufacturing process, reducing environmental impact and improving the overall efficiency of production.

Conclusion

3D printing has fundamentally changed how manufacturers approach product design, prototyping, and production. The combination of 3D printing technology with traditional manufacturing methods offers businesses greater flexibility, cost savings, and the ability to customize products in ways that were previously unfeasible. As additive manufacturing continues to evolve, it will undoubtedly continue to reshape industries, offering new opportunities for innovation and efficiency.

Get ready to upgrade your production operations with cutting-edge technology!

By3Design can help you take full advantage of the power of 3D printing for prototypes, small-batch production, and customized parts. Whether you're working on a new product line or need assistance with design iteration, By3Design is here to help you innovate and optimize.

Reach out today and start transforming your production process with 3D printing.

Navigation Links:

Contact Us:

Powered by Rae of Light SEO