3D Printing: What Materials Can You 3D Print With?

As the 3D printing revolution continues to gain momentum, cities like Phoenix are becoming hotspots for innovation in this transformative technology. Companies like By3Design are at the forefront, offering cutting-edge 3D printing Phoenix services to a wide range of industries. Whether you're an engineer working on prototypes, a designer bringing your vision to life, or a hobbyist experimenting with new creations, 3D printing provides endless possibilities.

One of the most crucial aspects of 3D printing is selecting the right material. With advancements in technology, the variety of materials available has expanded significantly, allowing users to 3D print objects that are not only aesthetically appealing but also functional and durable. If you're curious about what materials you can 3D print with, this post will explore the most popular options and their specific applications. See more on How 3D Printing is Shaping the Future of Education.

PLA (Polylactic Acid)

PLA is one of the most commonly used materials in 3D printing, especially for beginners. It’s a biodegradable thermoplastic derived from renewable resources like cornstarch or sugarcane, making it an eco-friendly option. PLA is easy to work with because it requires lower printing temperatures and doesn’t warp as much as other plastics.

Applications

- Prototypes and models

- Toys and figurines

- Containers and household items

Advantages

- Easy to print

- Affordable and widely available

- Environmentally friendly

- Minimal warping

Disadvantages

- Brittle compared to other plastics

- Not ideal for high-heat applications

Due to its ease of use and affordability, PLA is a popular choice among hobbyists and professionals alike in Phoenix’s 3D printing community.

ABS (Acrylonitrile Butadiene Styrene)

ABS is another popular material for 3D printing, known for its toughness and impact resistance. Unlike PLA, ABS is more durable and can withstand higher temperatures, making it suitable for functional parts and industrial applications.

Applications

- Automotive parts

- Electronic housings

- Tools and functional prototypes

- Toys like LEGO bricks

Advantages

- Strong and durable

- High impact resistance

- Heat resistant

Disadvantages

- Requires a heated bed for printing to avoid warping

- Emits unpleasant fumes during printing, so proper ventilation is required

ABS is widely used by companies in Phoenix for creating strong, functional parts that need to endure more wear and tear than items made from PLA.

PETG (Polyethylene Terephthalate Glycol)

PETG is a material that bridges the gap between PLA and ABS. It combines the ease of printing that comes with PLA and the durability of ABS. PETG is also food-safe, making it an ideal choice for applications that come into contact with food or beverages.

Applications

- Water bottles

- Food containers

- Medical supplies

- Transparent parts

Advantages

- Strong and flexible

- Chemical resistant

- Minimal warping and good adhesion

Disadvantages

- More difficult to print than PLA

- Requires careful calibration to avoid stringing

PETG is becoming more common in Phoenix’s 3D printing circles for producing items that require both strength and safety, especially in the food and medical industries.

TPU (Thermoplastic Polyurethane)

TPU is a flexible, rubber-like material often used in applications that need to be elastic and impact resistant. It’s commonly used for parts that require flexibility, such as phone cases or shoes.

Applications

- Phone cases

- Wearable technology

- Gaskets and seals

- Flexible prototypes

Advantages

- Extremely flexible

- Impact resistant

- Resistant to abrasion and wear

Disadvantages

- Challenging to print due to its flexibility

- Requires slower printing speeds

For clients in Phoenix looking for flexible and durable items, By3Design often recommends TPU. It’s perfect for creating parts that need to stretch, compress, or absorb impact.

Nylon

Nylon is a highly durable and flexible material, known for its excellent mechanical properties. It’s widely used in industrial applications due to its strength, wear resistance, and smooth surface finish.

Applications

- Gears and mechanical components

- Bearings

- Hinges

- High-strength prototypes

Advantages

- Strong and durable

- Resistant to wear

- Flexible

Disadvantages

- Sensitive to moisture (requires dry storage)

- Requires a heated bed for printing

Nylon is ideal for engineers and manufacturers in Phoenix who need functional, durable parts that can withstand stress and friction. By3Design offers nylon 3D printing for clients needing robust components for mechanical applications.

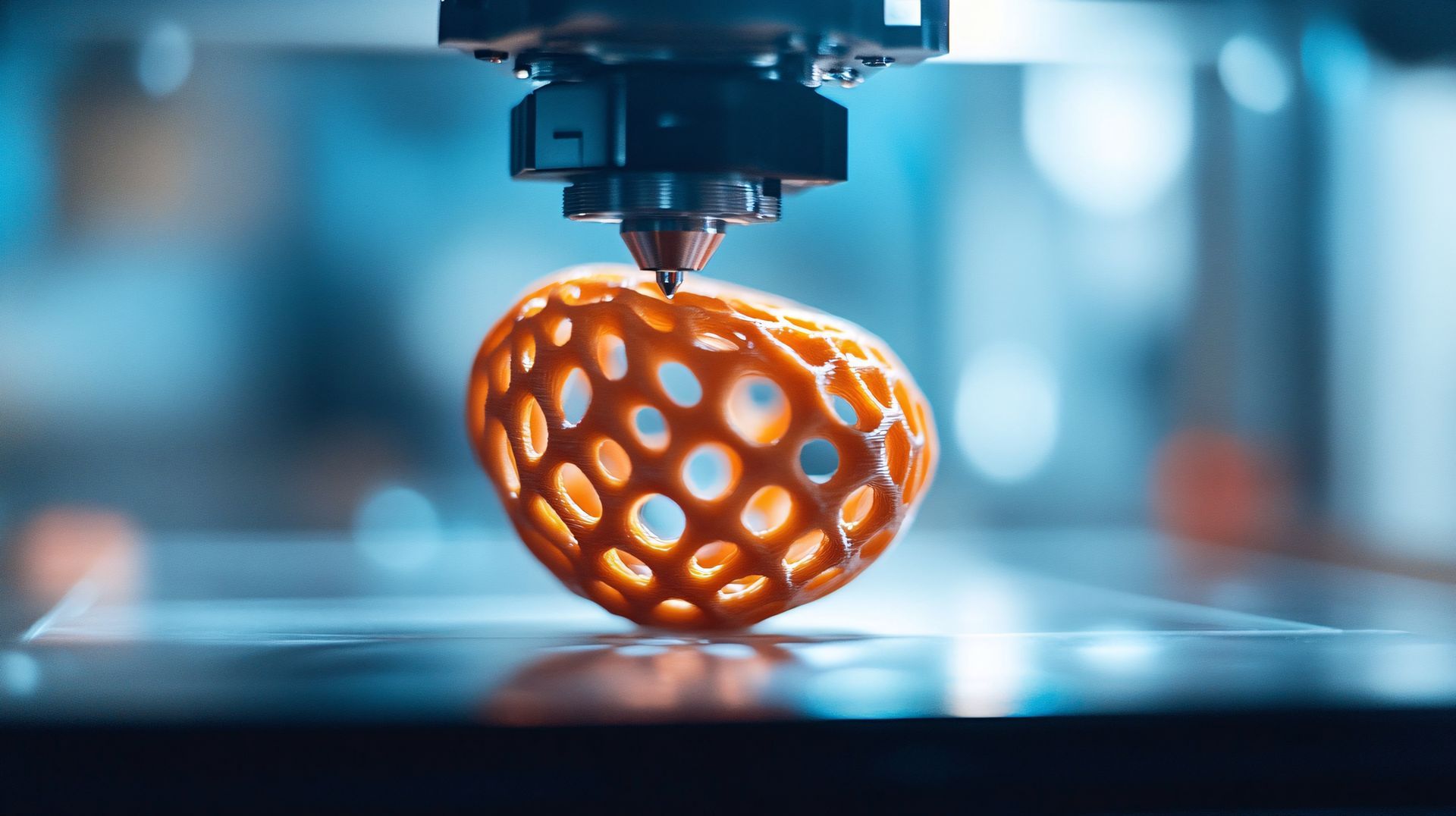

Resin

Resin is primarily used in SLA (Stereolithography) and DLP (Digital Light Processing) 3D printing, offering high levels of detail and smooth surface finishes. Resin-based prints are often used for intricate designs and parts that require precision.

Applications

- Jewelry

- Dental molds and medical models

- Miniatures and figurines

- High-detail prototypes

Advantages

- High level of detail

- Smooth surface finish

- Ideal for intricate designs

Disadvantages

- Brittle compared to other materials

- Requires post-processing (washing and curing)

By3Design’s resin 3D printing services are popular among Phoenix artists, jewelers, and medical professionals who need highly detailed and precise models.

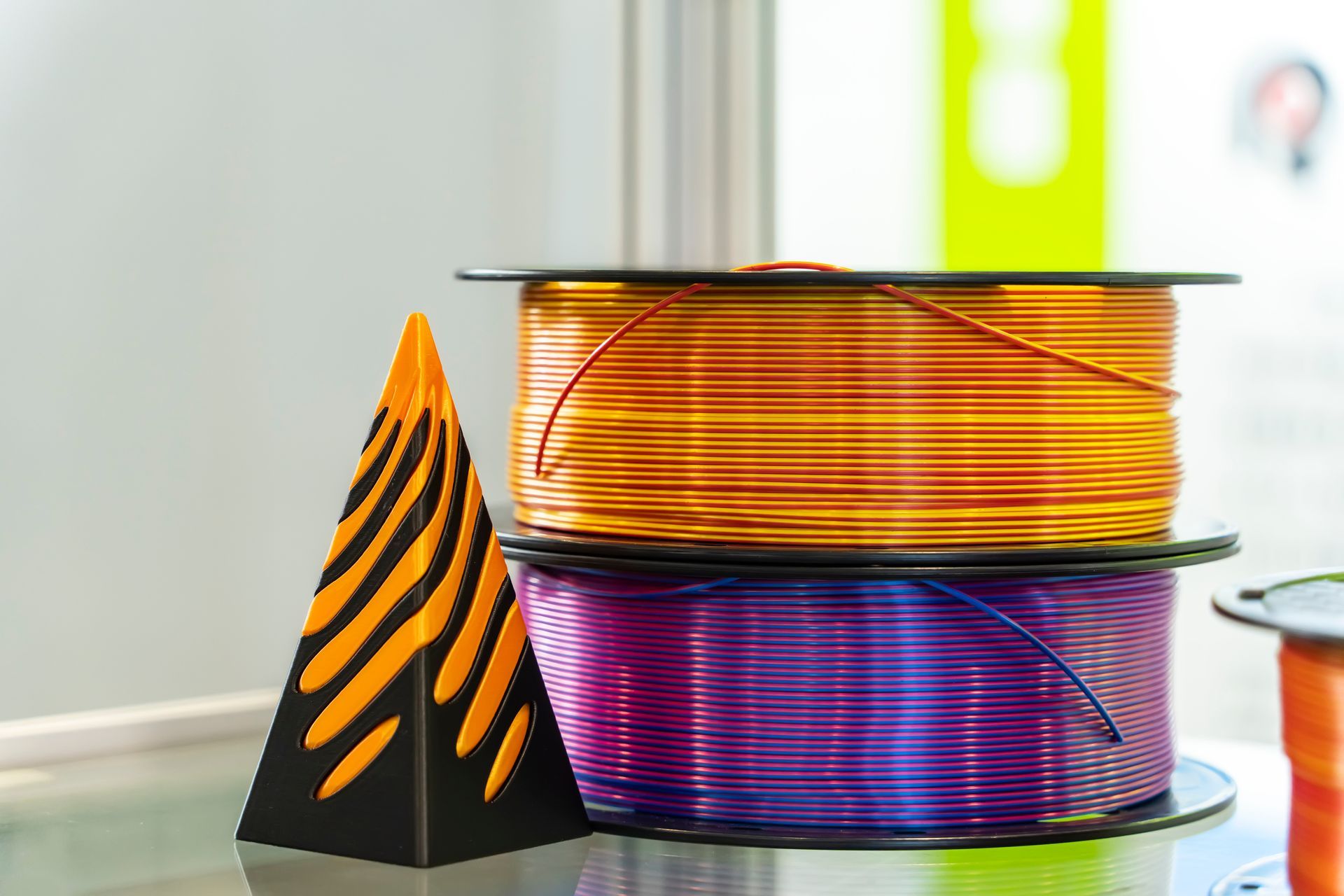

Carbon Fiber Reinforced Filaments

Carbon fiber reinforced filaments are a mix of standard thermoplastic materials like PLA, PETG, or nylon, infused with carbon fiber to enhance strength and rigidity. These filaments offer superior mechanical properties, making them ideal for applications that need high strength-to-weight ratios.

Applications

- Aerospace and automotive parts

- Drones

- Sporting equipment

- Strong, lightweight prototypes

Advantages

- Extremely strong and stiff

- Lightweight

- Great for structural components

Disadvantages

- Abrasive to printer nozzles (requires hardened nozzles)

- More expensive than standard filaments

Industries in Phoenix, such as aerospace and automotive manufacturing, benefit from By3Design’s carbon fiber reinforced filament 3D printing for producing lightweight yet strong components.

Metal Filaments

Metal filaments are made by blending metal powders with a base plastic, allowing you to create parts that have the look and feel of metal. Although these prints aren’t as strong as pure metal parts, they offer a metallic appearance and are useful for decorative purposes or low-load applications.

Applications

- Jewelry

- Sculptures

- Functional parts with metallic finish

- Decorative objects

Advantages

- Metallic look and feel

- Durable

Disadvantages

- Heavier than other filaments

- Requires post-processing for a true metallic shine

In Phoenix, designers and manufacturers often turn to By3Design for metal filament printing to create products that need a metallic appearance without the cost of traditional metal manufacturing.

Wood Filaments

Wood filaments are a mix of wood fibers and PLA, allowing you to 3D print objects that mimic the look and feel of real wood. These filaments can be sanded, stained, or painted, making them perfect for projects that require a natural, rustic aesthetic.

Applications

- Decorative objects

- Sculptures

- Furniture prototypes

Advantages

- Wood-like appearance

- Can be sanded and finished like real wood

Disadvantages

- More prone to clogging

- Brittle compared to standard PLA

Wood filaments are popular among artists and craftsmen in Phoenix looking to create unique, wood-like pieces using 3D printing.

Conclusion

The world of 3D printing is vast, and the material you choose can significantly impact the functionality and aesthetics of your final product. In Phoenix, By3Design offers a wide range of 3D printing services, helping businesses and individuals select the right materials for their projects.

Whether you’re working on a prototype, an artistic creation, or a functional part, understanding the different materials available for 3D printing is crucial. By3Design’s team of experts can guide you through the process, ensuring that your vision becomes a reality with the right materials.

As the demand for 3D printing continues to grow in Phoenix, the options for materials will only expand, offering even more possibilities for innovation and creativity. From biodegradable plastics to metal-infused filaments, the future of 3D printing is here, and it’s as versatile as the materials you choose.

Get in touch with By3Design today!

Navigation Links:

Contact Us:

Powered by Rae of Light SEO