3D Printing for Entrepreneurs: Turning Ideas into Reality

In recent years, 3D printing Arizona has emerged as a game-changer for entrepreneurs. Especially in Arizona, the technology has helped startups and small businesses streamline their product development processes. Entrepreneurs can now rapidly prototype, create customized designs, and reduce costs associated with traditional manufacturing. This has made it possible to turn creative ideas into tangible products faster and more efficiently. For entrepreneurs in Arizona, the ability to innovate without huge upfront investments in machinery has opened doors to a new realm of possibilities, transforming how products are developed, tested, and brought to market.

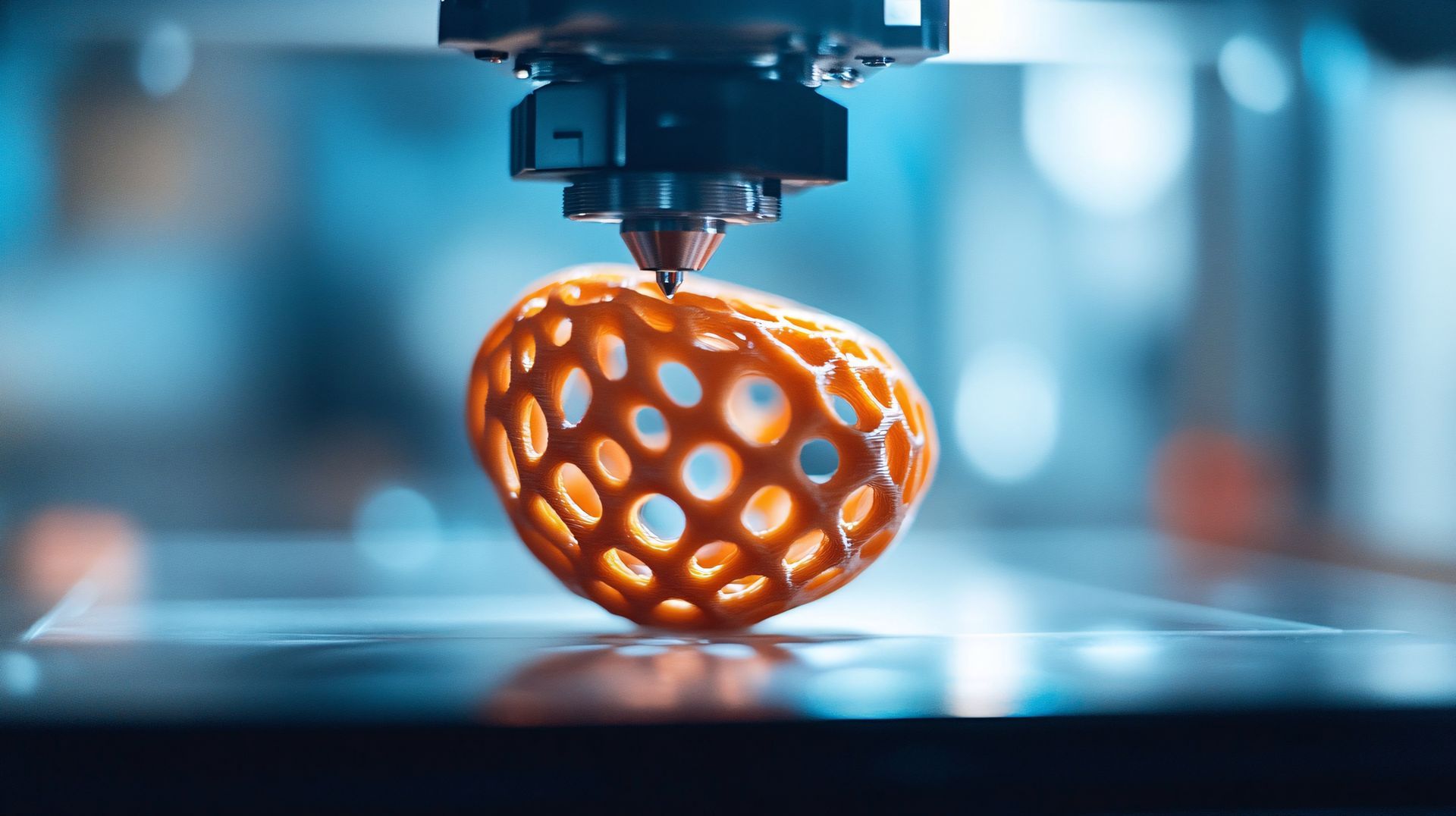

Using 3D Printing for Rapid Prototyping

3D printing's capacity to provide quick prototyping is one of its most notable benefits. This allows entrepreneurs to create a physical model of their product quickly, without the need for expensive molds or lengthy lead times. Learn the process of 3D printing when you read “How to Create a Model From Scratch: 3D Printing Guide.”

- Speed and Efficiency: With traditional manufacturing, prototyping can take weeks or even months. However, 3D printing reduces this time dramatically, allowing entrepreneurs to bring their ideas to life in a matter of days.

- Cost-Effective: Instead of investing in costly molds and machinery, 3D printing allows for cost-effective, low-volume production of prototypes. Entrepreneurs can create several iterations without significantly increasing costs, giving them the flexibility to refine their designs without breaking the bank.

- Design Flexibility: 3D printing allows for complex designs that would be impossible or extremely expensive to achieve with traditional manufacturing methods. Entrepreneurs can experiment with new ideas and iterate quickly, ensuring that the final product meets their expectations.

- Rapid Feedback and Testing: Entrepreneurs can gather immediate feedback from potential customers, investors, or focus groups by testing physical prototypes. This allows for quick adjustments, ensuring the product meets market demands before proceeding to mass production.

Low-Cost Product Testing and Iteration

One of the primary challenges for entrepreneurs is managing the cost of product development. Traditional manufacturing often requires expensive tooling, molds, and large production runs that can result in significant financial losses if a product fails. 3D printing eliminates these challenges, offering an affordable solution for testing and iteration.

- Affordable Testing: Entrepreneurs can use 3D printing to test their ideas before committing to large-scale production. Creating prototypes of different designs, materials, or features is less costly with 3D printing compared to conventional methods.

- Iterative Process: 3D printing supports the iterative nature of product design. Entrepreneurs can refine their designs multiple times without facing the high costs associated with traditional manufacturing. Each iteration can be tested and improved, leading to a more polished final product.

- Reduced Waste: Since 3D printing uses only the material necessary to create the product, waste is minimized. Entrepreneurs can prototype several variations of their product, without the environmental impact of traditional manufacturing processes.

- Faster Time-to-Market: With 3D printing, entrepreneurs can speed up their product development cycle. Prototypes can be tested and revised in a shorter period, meaning they can launch their products in the market more quickly and respond faster to consumer feedback.

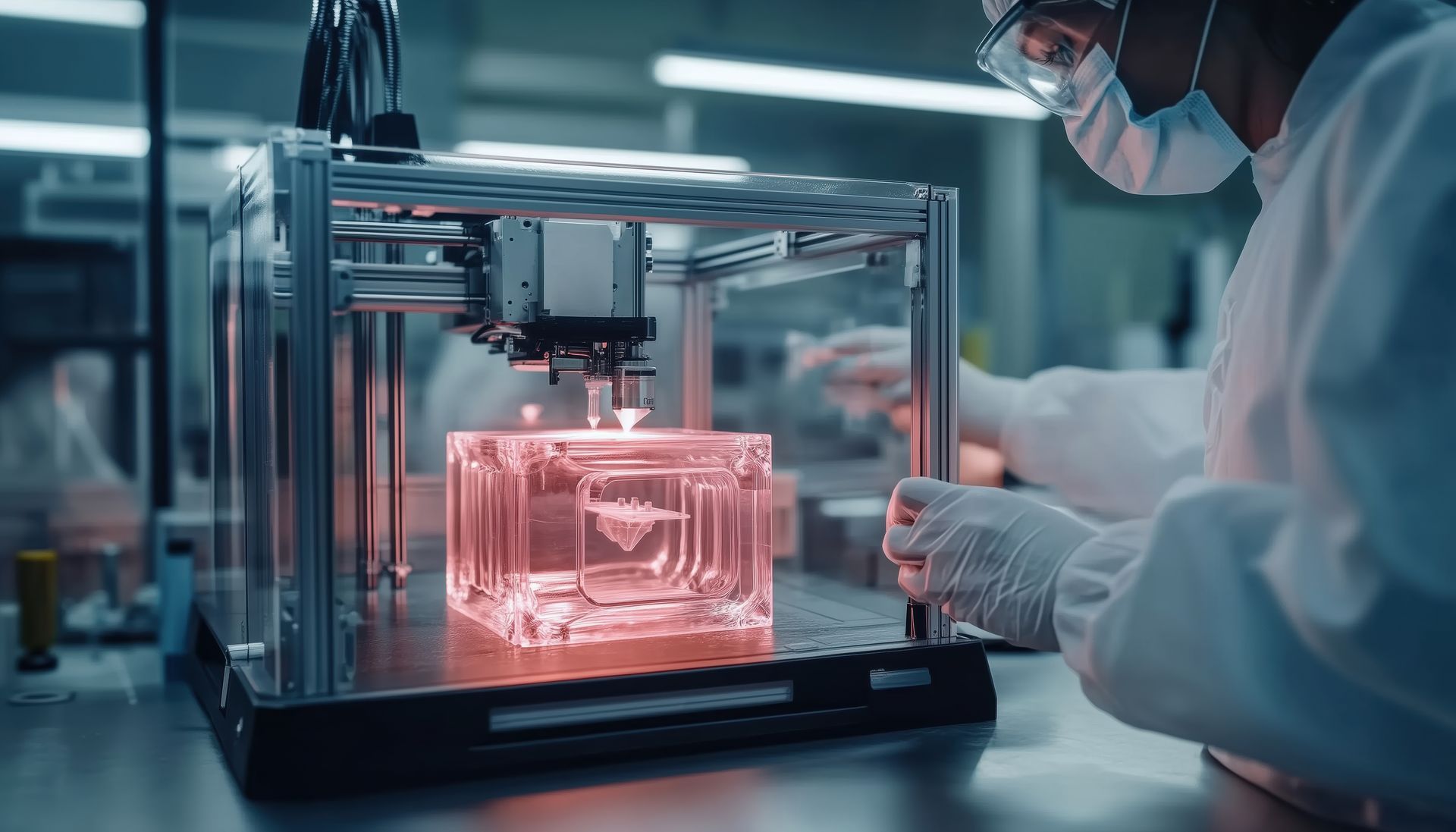

Customization Services for Niche Markets

3D printing offers an unparalleled opportunity for entrepreneurs to offer customized products tailored to niche markets. Whether it's bespoke jewelry, personalized gadgets, or specialized medical devices, 3D printing opens the door for small businesses to offer customized solutions to customers.

- Personalization: Entrepreneurs can create products that cater to individual preferences, such as custom-fit clothing or accessories. This personalization can help build a loyal customer base by offering unique, one-of-a-kind items.

- Localized Production: 3D printing allows entrepreneurs to produce products on demand, reducing the need for large inventories. This means entrepreneurs can cater to local or global markets more efficiently without the risks associated with overproduction.

- Access to Niche Markets: Entrepreneurs can target specific customer segments that require specialized products. For example, 3D printing can be used to design parts for niche hobbies, creating small batches of highly tailored items that larger manufacturers may overlook.

- Rapid Customization: With 3D printing, customizing a product doesn’t have to be a lengthy process. Entrepreneurs can quickly make adjustments to designs, materials, and sizes, allowing them to meet customer needs efficiently.

Examples of Businesses Built on 3D Printing

Several businesses have already taken advantage of 3D printing to build successful brands. From fashion to automotive, entrepreneurs across different industries have embraced this technology to offer innovative products and solutions.

- Formlabs: This company started with the idea of making 3D printing more accessible to a wider audience. They provide high-quality 3D printers for small businesses and entrepreneurs, allowing them to build and prototype their ideas more efficiently.

- Shapeways: Shapeways is an online marketplace where entrepreneurs can upload their designs and have them printed and shipped to customers. This model allows creators to turn their designs into products without the need for large-scale manufacturing or inventory management.

- Local Motors: This company specializes in building vehicles using 3D printing. They have created a range of innovative products, including 3D-printed car parts and even entire vehicles, showing the potential for 3D printing in large-scale production.

- Custom Jewelry Designers: Many jewelers now use 3D printing to create intricate, one-of-a-kind pieces. This allows small jewelry businesses to offer personalized designs without the need for expensive molds or casting processes.

Strategies for Scaling Production

While 3D printing offers numerous benefits for small-scale entrepreneurs, scaling production can present its own challenges. Entrepreneurs who want to take their business to the next level must consider several strategies.

- Automation: As demand grows, entrepreneurs can automate their 3D printing processes to speed up production. Investing in multiple 3D printers or more advanced printing systems can help increase throughput and meet customer demand.

- Outsourcing: Entrepreneurs can scale by partnering with 3D printing service providers who have the necessary infrastructure and capacity to handle larger production volumes. This allows entrepreneurs to scale their businesses without investing in expensive equipment or hiring additional staff.

- Material Variety: Using a broader range of materials can help scale the production of different products. By experimenting with different materials that suit mass production, entrepreneurs can offer a variety of products and expand their market reach.

- Distributed Manufacturing: Entrepreneurs can set up smaller production facilities closer to their target markets. This enables faster delivery times and reduces shipping costs, making the scaling process more efficient and cost-effective.

Conclusion

For entrepreneurs, 3D printing represents a transformative opportunity to bring ideas to life. With rapid prototyping, low-cost testing, and the ability to offer customized products, 3D printing paves the way for innovation. As businesses grow, entrepreneurs can scale their production by utilizing strategies like automation and outsourcing. With a forward-thinking approach, 3D printing can turn creative visions into successful ventures.

Ready to turn your ideas into reality? With By3Design's expert 3D printing services, you can bring your concepts to life faster and more efficiently. Whether you need rapid prototypes, customized designs, or scalable production,

By3Design is here to help you achieve your business goals. Don’t let traditional manufacturing slow you down—take advantage of 3D printing to streamline your processes and create innovative products.

Contact us today

and start shaping the future of your business!

Navigation Links:

Contact Us:

Powered by Rae of Light SEO